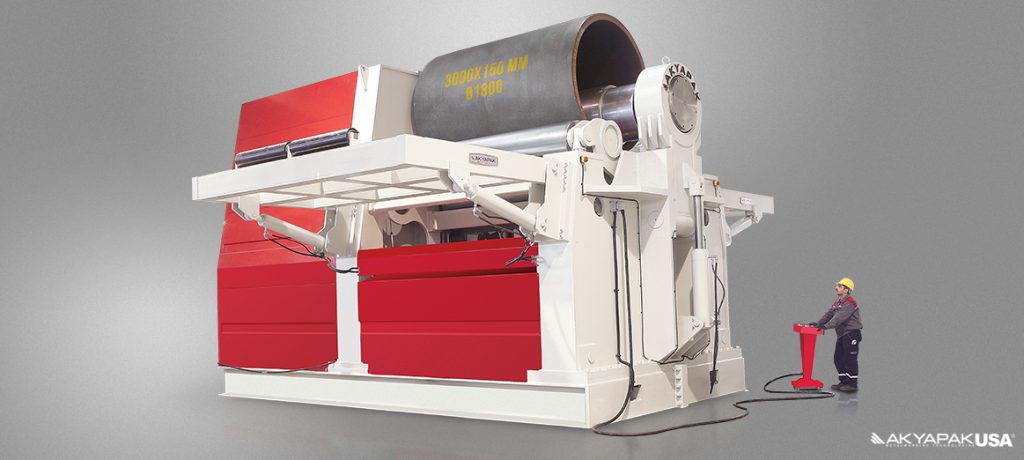

Akyapak AHS 4 Roll Plate Benders

see videos at bottom of page

Prescide, Productive and Reliable

As well as being reliable, AHS increases productivity with its high speed rolling ability and it overcomes the most challenging bends thanks to its ease of use. Since the plate is pinched during rolling, skidding and slipping of materials are prevented. Thus, more.

In AHS 4-Roll Plate Rolling Machines, one of the side rolls can be used as a squaring roll, thus the plate can be easily and precisely aligned along the roll across the input direction.

Great Solutions For Great Challenges

Akyapak manufactures 4 rolls hydraulic plate bending machines with capacity in thickness from 2 mm to 200 mm and in width from 500 mm to 12000 mm. (from 14 ga. to 8” and in width from 20” to 40ft.)

AHS-RK

As well as being reliable, AHS increases productivity with its high speed rolling ability and it overcomes the most challenging bends thanks to its ease of use. Since the plate is pinched during rolling, skidding and slipping of materials are prevented. Thus, more.

In AHS 4-Roll Plate Rolling Machines, one of the side rolls can be used as a squaring roll, thus the plate can be easily and precisely aligned along the roll across the input direction.

Less Flat Ends At a Single Pass

In AHS 4-Roll Machines, it is possible to achieve a full cylinder at a single pass because the material can be pinched with the lower-roll during pre-bending and bending. AHS model allows for precise pinching of the plate between upper and lower rolls, thus the.

AHS-RK

Akyapak offers special solutions for wind energy industry with AHS-RK Wind Tower Bending Line which it has developed. With its 55 years of experience and engineering and production expertise in many product groups, Akyapak is distinguished from its.

Akyapak designs the Wind Tower Bending Lines in an integrated way through the Welding Solutions it develops and produces. Akyapak Wind Tower Bending Lines that can be designed with Column-Boom systems and Rotators increases your productivity and.

Less Flat Ends At a Single Pass

In AHS 4-Roll Machines, it is possible to achieve a full cylinder at a single pass because the material can be pinched with the lower-roll during pre-bending and bending. AHS model allows for precise pinching of the plate between upper and lower rolls, thus the.

AHS-RK

Akyapak offers special solutions for wind energy industry with AHS-RK Wind Tower Bending Line which it has developed. With its 55 years of experience and engineering and production expertise in many product groups, Akyapak is distinguished from its.

Akyapak designs the Wind Tower Bending Lines in an integrated way through the Welding Solutions it develops and produces. Akyapak Wind Tower Bending Lines that can be designed with Column-Boom systems and Rotators increases your productivity and.

AHS-T

AHS-T Tank Bending Machine is designed with Akyapak’s 55 years of experience and engineering expertise. AHS-T easily performs the bending of tanks containing multi-radius at one pass. Akyapak, continuously improving technological infrastructure of the.

The diameters of rolls in AHS-T machine are small and supports are placed for preventing all the rolls from deflecting. AHS-T which can produced in different dimensions for various applications reflects the expertise of Akyapak in “tailor-made” solutions.

AHS-PM

AHSPM being among the special solutions that Akyapak offers for the specific needs of the industry is designed to show high performance for long pipes with relatively narrow diameters.

In AHS-PM model offering high productivity in pipe production, the upper roll is designed as pre-stressed in order to compensate deflections. The upper roll can be changed very fast for various pipe diameters and thicknesses.

AHS-V

AHS-V Vertical Plate Rolling Machine is an ideal solution for bending in wide diameters or bending in a half-cylinder form. AHS-V which is another solution of Akyapak for the specific needs of the industry requires less space with its vertical feature.

Standard Equipments;

- Cone bending device

- Induction hardened rolls

- Digital display for side rolls

- Fully welded steel (St-52) construction body

- Separate moving control panel

- Two rolling speeds

- Electro-hydraulic calibration

- All rolls are mounted in roller spherical roller bearings

- Safety equipment around the machine

- Central rolls are driven by hydraulic motors and planetary gearboxes

- Certified by CE, ISO9001 – 2008, TSEK and TURQUM

Optional Equipments;

- Central and side supports

- Variable speed of rotation

- Material feeding table with various features

- Interchangeable top roll

- Oil cooling system

- Driven side rolls

- Automatic material ejection equipment

- Automatic loading and unloading system

- Deflection compensating system

- Motors in variable voltage and frequency

- CNC

- NC