Bend-Tech

click images to enlarge, videos at bottom of page

Dragon A400 CNC Plasma Tube & Pipe Cutter (Angle and Channel Options Available)

The Essential CNC Tube Production Machine

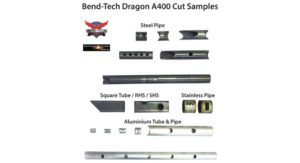

Processing tube and pipe can be one of the most laborious areas of production. The Dragon A400 uses plasma cutting, marking, and engraving to make CAD/CAM designs a reality. Any design of holes and end cuts can be plasma cut on the Dragon A400. Plasma cutting offers a fast and accurate method of cutting tube and pipe without the high cost of a laser system. The machine marks clear bending instructions such as bend location, rotation, and degrees on the tube. These bending instructions can be calibrated to your specific benders. For shops that fabricate with tube and pipe, the Dragon A400 is the essential tool for success.

Increase Production with Full Automation

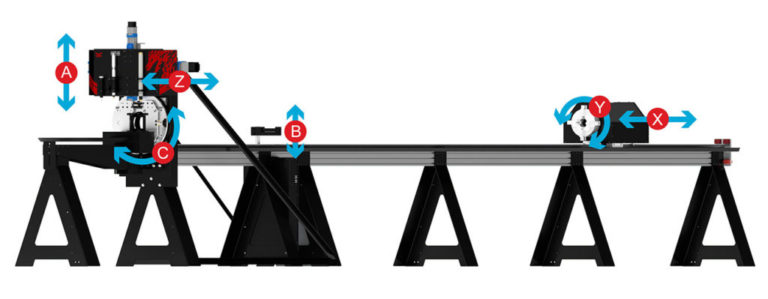

6 Axes of Movement

A & Z Axes

Provides accurate side to side and up/down movements of the toolhead and its tools.

X-Axis

A precision rack and anti-backlash pinion drive system moves the material along its length.

Y-Axis

Works in unison with the C-axis to rotate the material.

B-Axis

Ensures that long pieces of material maintain being level throughout the cutting process.

C-Axis (Optional Feature)

Works in unison with the Y-axis to rotate the material.

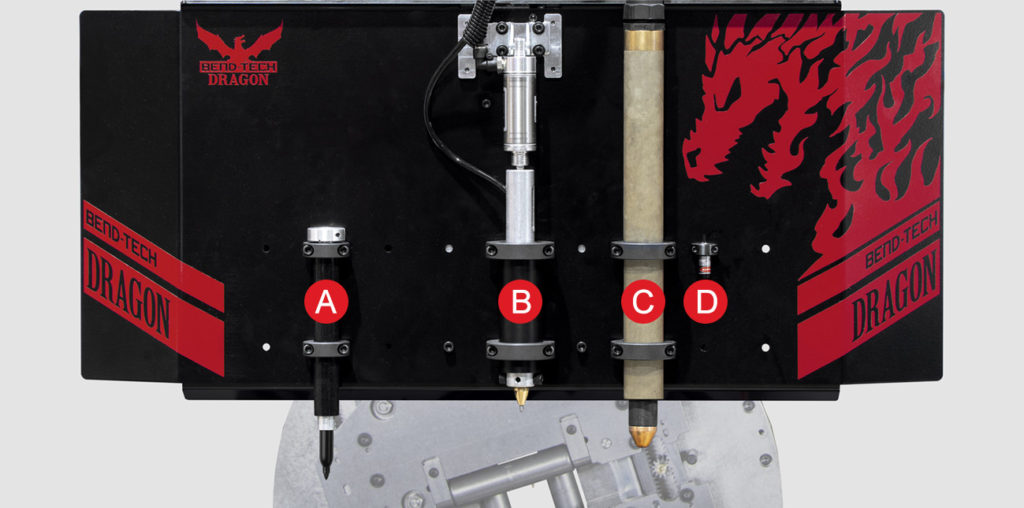

- The Bend-Tech Dragon tool changer comes with a plasma torch mount, permanent marker with mount, an engraver with mount, and laser light and mount.

- The automated CNC tool changerallows for marking, engraving, and cutting to occur seamlessly at the push of a button.

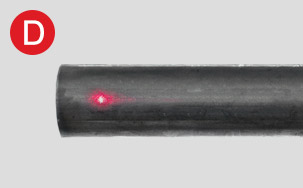

- The Laser light provides accurate calibration and alignment of material during the loading process with the machine.

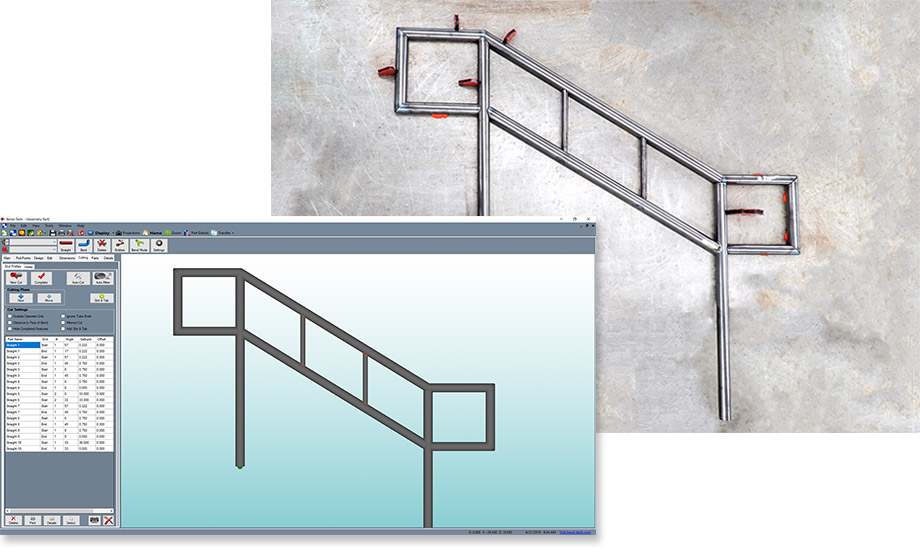

Design To Production Made Easy With Powerful CAD & CAM Software

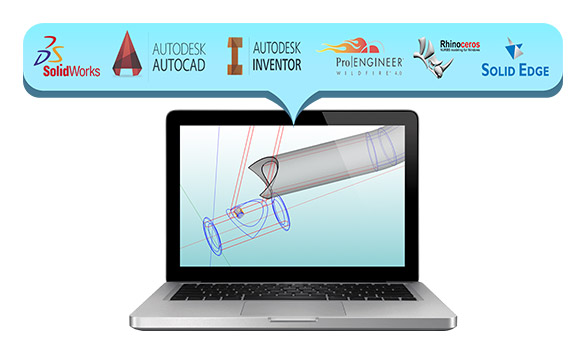

Import Your 3D Parts or Design from Scratch

Import 3d CAD designs or create them from scratch with the Bend-Tech Dragon CAD. The Dragon Cad imports Step & IGES files that are supported by most CAD software. Some of the compatible software is pictured to the right. Once imported, the Dragon Cad will trace all your Cad geometry and convert it into a CAM ready file. This process normalizes along the cut path for a weld ready part. The CAM ready file is read by the Dragon A400 for CNC production

Full Machine Control

The Dragon software gives full control of the dragon machine to the operator. The operator is able to move all axes, control speed, and start or stop the job when needed. The G-code viewer is available to see each action in detail, With the click of a button, homing the machine is easy. The control panel includes an Emergency Stop button for safety.

Available Add-Ons For Your Dragon

There are three amp levels of Powermax plasma systems recommended for use on the Bend-Tech Dragon. The Hypertherm Powermax systems come with a 25′ lead. The level of Powermax system required varies based on multiple factors. The Dragon requires a mechanized plasma torch. To best decide what level of Powermax system required, contact us.