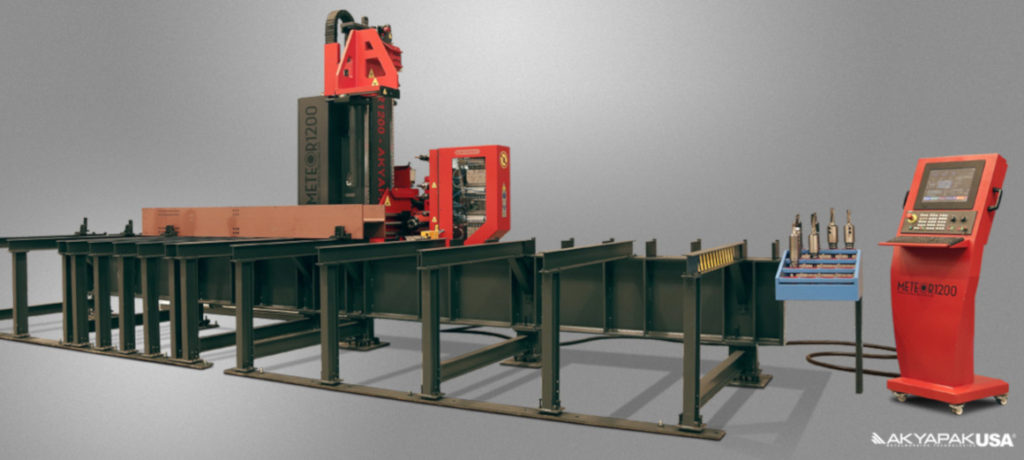

Akyapak Meteor 1200

Single Spindle Drill Line

click on images to enlarge

AKYAPAK METEOR-1200 is developed to drill any kind of profile by rotating the beam. The tight tolerance between the holes is not a matter anymore since day by day steel producers needs more accurate manufacturing and assembling in shorter time. The time is many so METEOR-1200 is ready to reduce your labor either for drilling or for on-site assembly. METEOR-1200 is ready to drill beams, angles, flat sheets and any suitable geometry. You can also mill slots, pockets and any geometry by having state of arts control system.

Akyapak Meteor 1200 gives you advantages;

- Affordable investment

- Optimum price/quality ratio

- Highest driving Powers in the market

- 11 kw spindle power

- High positioning tolerance and repeatability

- Very robust design

- Worldwide spare parts availability

- Easy to operate, high versatility

- User friendly control system

- Reduced size of overall dimensions

- Speedy, accurate and free of maintenance

- Heavy duty usage

- Great flexibility

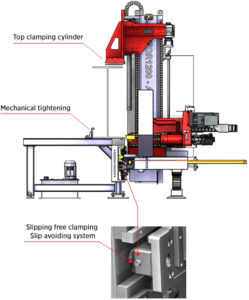

Clamping system

By means of 2 cylinder, the cabinet and work piece being clamped. Upper clamp cylinder clamps the piece strongly to avoid any movement during the processing. Lower cylinder clamps the cabinet against the support table. By this way, the piece and cabinet is strongly fixed during the processing.

The mechanical movement of the part is prevented by mechanical compression.

Standart Features:

- Control Panel: SIEMENS

- Drilling Unit: 1

- Rill Chuck Cone / Spindle Head Tool Shafts hole: BT40, suitable for ATC system

- Working length: 12000 mm (2000x6000x8000x18000 OPSİYON)

- Profile height: 50 mm – 1200 mm

- Profile width: 50 mm – 1200 mm

- Support table height: 1200 mm

- Length: 17469 mm

- Height: 3299 mm

- Width: 3721 mm

- Weight: 12000 kg

- Maximum tool length: 300 mm

- Tapping: M12 – M20

- Drilling capacity: 10 – 32 mm tool with replaceable carbide head / 40 mm with U-tool

- RPM: 3000 rpm

- Spindle Power: 11 kW

- Total Power: 45 kW

- Tools ATC: 6 AD..