Cidan

click on images ti enlarge, videos at bottom of page

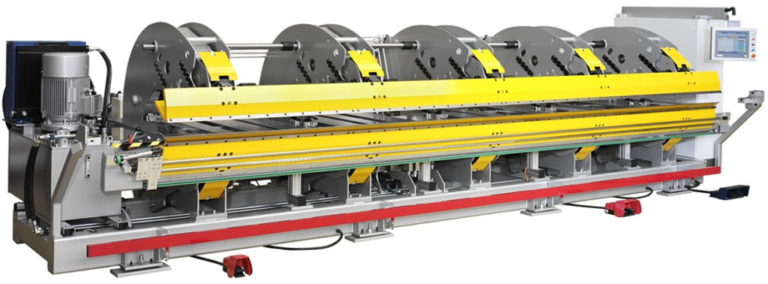

Thalman TZ Folding Machines Long

The Thalmann TZ long metal folder series is the uniquely built next generation of the proceeding THAKO and ZR models. Uniting centuries of Swiss engineering, this long folder utilizes the time tested and innovated Vertical Force Drive (VFD) design principle, which is second to none. With the machine stands forming the shape of “rigid C-frames” and its vertical tool alignment, the VFD produces the maximum amount of vertical clamping force. The TZ long metal folder uses the perfect combination of design principles and technology to produce the perfect fold every time for a very long time.

- VFD (Vertical Force Drive) design principle

- Control Shaft Technology

- Newly designed clamping beams and the offset folding beam

- Dynamic Crowning System

- Newly designed Longitudnal Slitter

Thalmann TD Double Folder

The Thalmann TD metal double folder utilizes 2” (50 mm) torsion drive shafts on the folding and upper beam movement. With a total of five torsion shafts and the double folder’s pension for ensuring parallelism, the Thalmann TD is one of the best machines in regard to forming radius parts and the overall longevity of the machine. The incredible accuracy of this double folder is derived from the rotary encoders application directly on the torsion shaft. The torsion drive shafts completely eradicate the “twisting” that generally occurs over time. That means the TD metal double folder will produce an accuracy of +/- .02” (.5 mm) from its first fold to its last.

- Tool geometry with 275° free space

- Offset folding beam geometry

- Fully-automatic gripper system

- Multi-section gripper function

- Highly dynamic DFT drive

- Kinetic control shaft technology

- High-performance hydraulics with oil cooler

- Remote maintenance using TeamViewer software

- Low-friction CDF supporting table

- Multi-zone folding beam crowning

- Graphic CNC touch-screen controller

Thalmann TC Double Folder

The Thalmann TC metal double folder is often affectionately and respectfully referred to as “Big Mama” – due in large part to its solid construction. Of the 11,564 hand-crafted, high-quality parts that make up this double folder, the five 2” (50 mm) torsion drive shafts on the folding and upper beam movement give this machine its reputation of accuracy and longevity. Like the TD, the accuracy of the “Big Mama” is derived from the rotary encoders application directly on the torsion shaft. The torsion drive shafts completely eradicate the “twisting” that generally occurs over time. That means the TC metal double folder will produce a 60-bend part with an incredible end to end deviation of .070” (2 mm)!

- VFD design principle

- Offset folding beam geometry

- Fully-automatic gripper system

- Multi-section gripper function

- Highly dynamic DFT drive

- Kinetic control shaft technology

- High-performance hydraulics with oil cooler

- Remote maintenance using TeamViewer software

- Low-friction CNS supporting table

- Multi-zone folding beam crowning

- Graphic CNC touch-screen controller