Sunrise PM-35T ~ PM-200XT

click on images to enlarge, videos at bottom of page

Sunrise Punching Non CNC

This is Sunrise Punching Non CNC patented dual-piston hydraulic cylinder enables the machine to retract faster, and also makes our cylinder slimmer, which brings a better appearance to the machine.

– Punching machines ranging from 35 to 200 tons of punching capacities, combined with different throat depths to choose from, provides a complete range of models to meet our customer’s wide range of requirements.

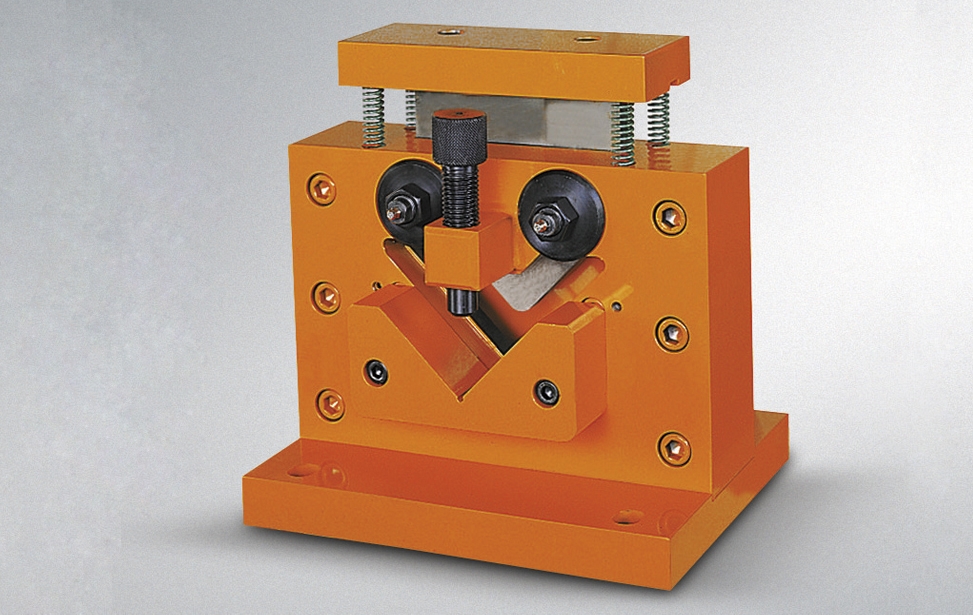

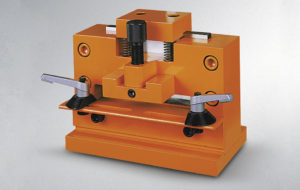

– All optional tooling used on the punching station of S/SD ironworkers can also be used on the PM models, turning the punching machine into a universal machine.

- * Rectangular notcher.

- * Bar shearing.

- * Channel shearing.

- * Angle shearing.

- * Flat bar shearing.

- * Rectangular notcher.

- * Bar shearing.

Specifications

| Model | PM-35T PM-35LT PM-35XT | PM-55T PM-55LT PM-55XT | PM-80T PM-80LT PM-80XT | PM-120LT PM-120XT | PM-160LT PM-160XT | PM-200LT PM-200XT |

| Punching | ||||||

| Punching Force | 35 Ton | 55 Ton | 80 Ton | 120 Ton | 160 Ton | 200 Ton |

| Punch Capacity | ø18 x 14 | ø22 x 18 | ø25 x 23 | ø32 x 27 | ø36 x 32 | ø41 x 35 |

| (Diameter x Thickness) | ø50 x 5 | ø50 x 8 | ø50 x 12 | ø50 x 17 | ø50 x 23 | ø50 x 29 |

| Throat Depth (T) | 310 | 310 | 310 | – | – | – |

| Throat Depth (LT) | 510 | 510 | 510 | 510 | 510 | 510 |

| Throat Depth (XT) | 760 | 760 | 760 | 760 | 760 | 760 |

| Max. Stroke Length | 100 | 100 | 100 | 100 | 100 | 100 |

| Cycles / Min. (20mm stroke) | 41 | 28 | 28 | 26 | 27 | 28 |

| Table Size (W x D) (T) | 700 x 500 | 700 x 500 | 700 x 500 | – | – | – |

| Table Size (W x D) (LT) | 700 x 700 | 700 x 700 | 700 x 700 | 700 x 700 | 700 x 700 | 700 x 700 |

| Table Size (W x D) (XT) | 700 x 950 | 700 x 950 | 700 x 950 | 700 x 950 | 700 x 950 | 700 x 950 |

| Working Height Up to Die | 1050 | 1050 | 1050 | 1050 | 1050 | 1050 |

| Optional Tooling | ||||||

| Largest Hole* | ø160 x 2 | ø160 x 3 | ø160 x 4 | ø160 x 5 | ø160 x 6.5 | ø160 x 8 |

| Single Vee Press Brake (W x T)* | 250 x 12 | 250 x 12 | 250 x 12 | 250 x 20 | 250 x 20 | 250 x 20 |

| Multi Vee Press Brake (W x T)* | 500 x 3 | 500 x 5 | 500 x 5 | 700 x 5 | 700 x 5 | 700 x 5 |

| Angle Bending* | 65 x 65 x 8 | 75 x 75 x 6 | 100 x 100 x 7 | 100 x 100 x 13 | 100 x 100 x 13 | 100 x 100 x 13 |

| Rectangular Notcher (WxDxT)* | 63.5 x 90 x 5 | 63.5 x 90 x 6 | 63.5 x 90 x 8 | 63.5 x 90 x 10 | 63.5 x 90 x 10 | 63.5 x 90 x 10 |

| Vee Notcher (Side x Side x T)* | 145 x 145 x 4 | 145 x 145 x 6 | 145 x 145 x 10 | 145 x 145 x 12 | 145 x 145 x 12 | 145 x 145 x 12 |

| Pipe Notcher (Max diameter)* | ø100 | ø100 | ø100 | ø100 | ø100 | ø100 |

| Flat Bar Shearing* | 175 x 5 | 175 x 7 | 175 x 10 | 175 x 14 | 175 x 14 | 175 x 14 |

| Angle Shearing* | 65 x 65 x 8 | 75 x 75 x 6 | 100 x 100 x 7 | 100 x 100 x 13 | 100 x 100 x 13 | 100 x 100 x 13 |

| Round Bar Shearing* | ø28 | ø32 | ø32 | ø32 | ø32 | ø32 |

| Square Bar Shearing* | 28 x 28 | 32 x 32 | 32 x 32 | 32 x 32 | 32 x 32 | 32 x 32 |

| Channel Shearing (H x B)* | – | 100 x 50 | 100 x 50 | 100 x 50 | 100 x 50 | 100 x 50 |

| Vee Press Brake (W x T)* | 250 x 12 | 250 x 15 | 250 x 15 | 250 x 20 | 250 x 20 | 250 x 20 |

| Multi Vee Press Brake (W x T)* | 500 x 3 | 500 x 5 | 500 x 5 | 700 x 5 | 700 x 5 | 700 x 5 |

| Angle Bending* | 102 x 6 | 102 x 9 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 |

| Rectangular Notcher (W x D x T)* | 63.5 x 90 x 6 | 63.5 x 90 x 8 | 63.5 x 90 x 10 | 63.5 x 90 x 13 | 63.5 x 90 x 13 | 63.5 x 90 x 13 |

| Vee Notcher (Side x Side x T)* | 145 x 145 x 5 | 145 x 145 x 6 | 145 x 145 x 10 | 145 x 145 x 12 | 145 x 145 x 13 | 145 x 145 x 13 |

| Pipe Notcher (Max diameter)* | ø100 | ø100 | ø100 | ø100 | ø100 | ø100 |

| Flat Bar Shearing* | 175 x 5 | 175 x 7 | 175 x 10 | 175 x 14 | 175 x 16 | 175 x 16 |

| Angle Shearing* | 75 x 75 x 6 | 100 x 100 x 7 | 100 x 100 x 10 | 100 x 100 x 13 | 100 x 100 x 13 | 100 x 100 x 13 |

| Round Bar Shearing* | ø32 | ø32 | ø32 | ø32 | ø32 | ø32 |

| Square Bar Shearing* | 28 x 28 | 32 x 32 | 32 x 32 | 32 x 32 | 32 x 32 | 32 x 32 |

| Channel Shearing* | — | 102 x 51 | 102 x 51 | 102 x 51 | 102 x 51 | 102 x 51 |

* : Optional Tooling

Based on low carbon / mild steel material strength of 45kg / mm² tensile. Design and specifications subject to change without notice. A 2-hole overhang die holder and a 2-piece gauging table are provided as standard equipment on all punching machines.